Custom boards need to activate the screen and ensure normal operation, involving several technical challenges, including:

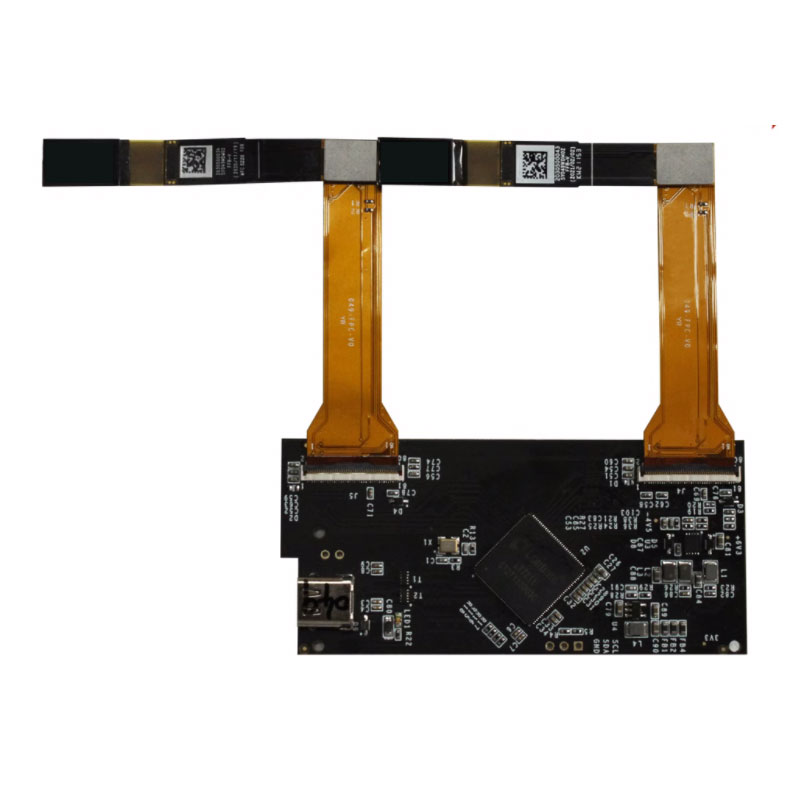

1. Connection and Conduction Technology:

1. The OLED screen on custom boards requires connection and conduction on a micron-level contact surface, demanding high precision and accuracy in technology.

2. The lighting test for OLED flexible displays is more complex than traditional LCDs, requiring each pixel to light up independently, posing challenges for circuit design and connection technology.

2. High-Precision Press-Fit Technology:

1. Precise press-fitting of display panels is a crucial part of the panel detection process, significantly improving detection accuracy and reducing product loss.

2. Custom boards need to employ high-precision press-fit technology to ensure a stable connection between the screen and the main board, guaranteeing accurate signal transmission.

3. Current and Connector Technology:

1. OLED screens require a larger current for testing, while the BTB connector pitch value for connecting the screen is relatively small, presenting a technical challenge for screen activation and panel detection.

2. It is necessary to develop connectors suitable for high current and small pitch values to ensure stable current transmission and normal screen operation.

4. Material and Technology Selection:

1. Material selection for custom boards must consider properties such as conductivity, thermal conductivity, and temperature resistance to ensure stable performance over long-term use.

2. In terms of technology selection, suitable manufacturing processes and testing technologies must be chosen based on the specific requirements of the custom board to ensure product quality and performance.

5. System Design and Optimization:

1. Custom boards need a well-designed system architecture, including power management, signal processing, and screen driving modules, to ensure system stability and reliability.

2. System optimization involves performance enhancements tailored to specific application scenarios, such as reducing power consumption and improving response speed.

6. Testing and Verification Technology:

1. Strict testing and verification are required during the production process of custom boards to ensure the quality and performance meet design requirements.

2. Testing and verification technologies include, but are not limited to, performance testing, reliability testing, and compatibility testing.

In summary, custom boards need to activate the screen and ensure normal operation, involving technical challenges in connection and conduction technology, high-precision press-fit technology, current and connector technology, material and technology selection, system design and optimization, and testing and verification technology. Solving these technical challenges requires the integrated application of knowledge and technologies from materials science, electronic engineering, computer science, and other fields.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: global08@eurotech-ic.com

https://www.eurotech-ic.com/