Differences Between Rigid and Flexible Components in Mechanical and Manufacturing Fields

Rigid and flexible components exhibit distinct differences in mechanical, manufacturing, and related fields. Here is a detailed explanation of these differences:

Definition and Characteristics:

- Rigid Components: These refer to objects that resist deformation when subjected to force. They do not bend or twist easily. Their mechanical characteristic is that they do not undergo significant deformation under any external load, which can be understood as an elastic body with an elastic modulus tending to infinity.

- Flexible Components: In contrast to rigid components, these parts are described by their ease of deformation or rotation. They typically need to have some degree of elasticity and flexibility to meet specific requirements.

Application Scenarios:

- Rigid Components: These are commonly used in situations requiring high strength and precision, such as high-speed rotating machines and high-strength environments. In such cases, rigidity prevents part deformation, enhancing operational safety and stability.

- Flexible Components: In complex assembly environments or in high-temperature or high-pressure conditions, flexible components can adjust their position more easily, avoiding deformation or damage. For example, bellows expansion joints are flexible elements that absorb large deformations, primarily used for vibration isolation and noise reduction.

Design and Selection:

- Rigid Components: When designing or selecting materials, factors such as application scenarios, production costs, material weight, and strength must be considered. In some cases, rigidity is the primary consideration because it ensures system stability and reliability.

- Flexible Components: The design process must account for their compensation capacity, space requirements, resistance, material consumption, and ease of installation. Additionally, due to the significant variation between products from different manufacturers, the actual data of the selected sample must be used in computational software.

Forms and Types:

- Rigid Components: In practical applications, rigid components may take various forms, such as rigid connections or rigid supports.

- Flexible Components: These typically include elements with low rigidity, such as bellows expansion joints and sleeve compensators. They are widely used in scenarios requiring thermal compensation.

In summary, rigid and flexible components differ significantly in definition, characteristics, application scenarios, design and selection, and forms. In mechanical, manufacturing, and related fields, the correct selection and use of these components are crucial to ensuring system stability and reliability.

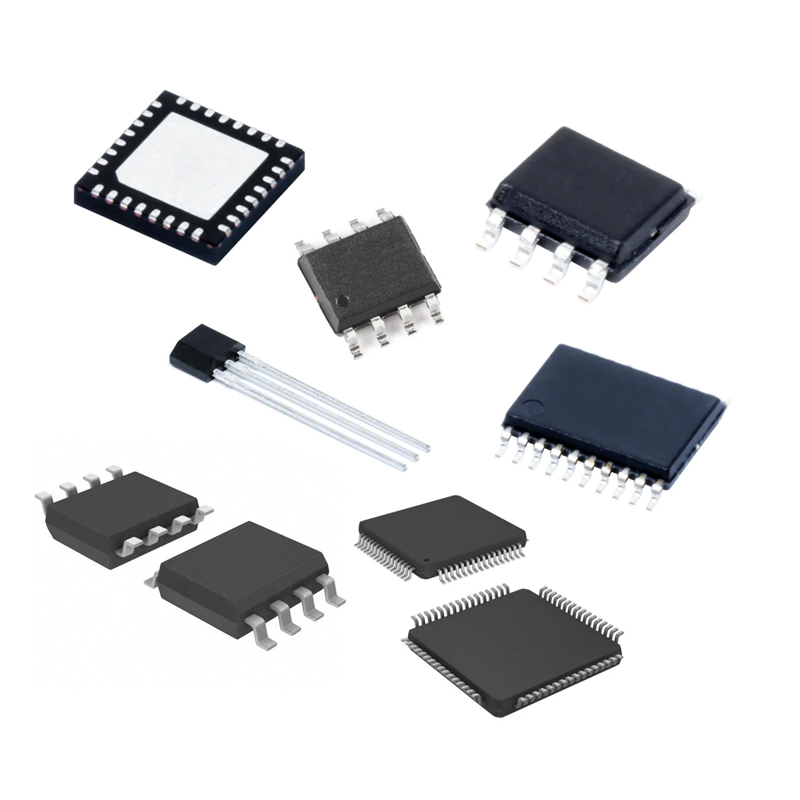

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: global08@eurotech-ic.com

https://www.eurotech-ic.com/