Using acetone to clean oxidized chips can potentially damage the chip. Acetone is a polar solvent with excellent dissolving capabilities, often used to remove organic contaminants such as photoresist and grease. However, acetone can also dissolve or corrode the materials on the chip's surface, particularly if there are oxidation layers or other protective coatings. These coatings are typically applied to protect the chip surface and enhance its conductivity. If acetone dissolves or corrodes these coatings, it can lead to chip failure or degraded performance.

Therefore, when dealing with oxidized chips, it is essential to use acetone and other organic solvents cautiously. If acetone must be used, it's crucial to understand the materials and coatings on the chip surface and follow professional advice. Alternatively, safer and milder cleaning methods, such as using deionized water or specialized chip cleaning agents, should be considered.

When cleaning an oxidized chip, it's advisable to use specialized chip cleaning agents or water-based rosin cleaners to ensure safety and effectiveness. These cleaners are designed to remove contaminants, including oxides, from the chip surface and are generally safe for chip materials.

While using cleaning agents, it's essential to follow the product instructions carefully and avoid overuse. During the cleaning process, other parts of the chip should be protected to prevent unnecessary damage. In addition to cleaning agents, physical methods like gently sanding the pin surface with fine sandpaper can also help remove oxidation layers. However, this method requires careful handling to avoid damaging the pins or other parts of the chip.

In summary, when dealing with oxidized chips, it is crucial to choose the appropriate cleaning agents and follow the correct procedures to ensure safe and effective cleaning.

Dilution of Chip Cleaning Agents

Whether a chip cleaning agent needs dilution depends on the specific cleaner and its intended use. Some cleaning agents are pre-mixed at optimal concentrations and can be used directly. Others may require dilution to achieve the best cleaning results. The concentration choice depends on the chip material type, cleaning requirements, and cleaning methods (such as soaking, spraying, or ultrasonic cleaning).

Before using a chip cleaning agent, it is advisable to read the product instructions carefully or consult the manufacturer to understand the recommended usage and concentration. Following the manufacturer's guidelines ensures effective cleaning while avoiding damage to the chip.

General Steps for Diluting Chip Cleaning Agents

1. Read the Instructions: Start by thoroughly reading the cleaning agent's instructions to understand the recommended dilution ratio and procedure.

2. Prepare Tools and Materials: Gather the necessary cleaning agent, distilled or deionized water, a clean container, and stirring tools.

3. Measure the Cleaning Agent and Water: Use precise measuring tools (such as a graduated cylinder) to measure the required amounts of cleaning agent and water according to the recommended ratio.

4. Mix: Pour the measured cleaning agent into the container, then slowly add the water. Stir gently with the stirring tool to ensure thorough mixing.

5. Check Concentration: If necessary, use appropriate tools (such as a refractometer) to verify that the diluted cleaning agent meets the required concentration.

6. Store: Store the diluted cleaning agent in an appropriate container, labeling it with the dilution ratio and date of preparation.

Different types of cleaning agents may require different dilution methods and ratios. Therefore, always read the instructions and follow the manufacturer's recommendations. To avoid cross-contamination and ensure cleaning effectiveness, use clean containers and tools for dilution and storage.

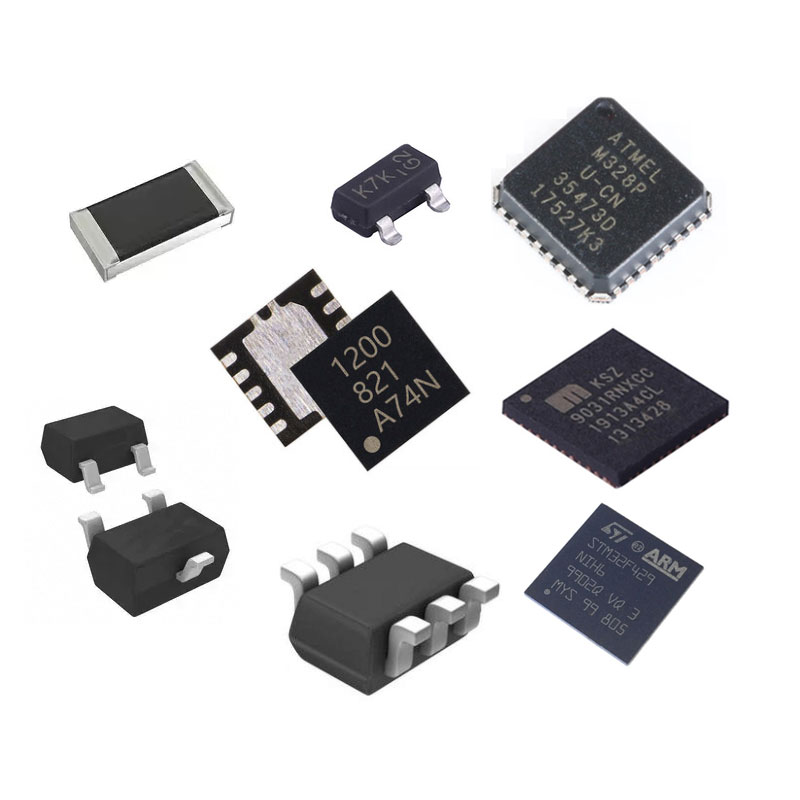

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: global08@eurotech-ic.com

https://www.eurotech-ic.com/