When chip pins become oxidized, you can take the following steps to repair them:

1. Prepare Tools and Materials: You will need a small file, fine sandpaper, an alcohol swab, and a non-acidic cleaner. Additionally, prepare a small bottle of conductive adhesive and a small bottle of anti-oxidation liquid.

2. Remove the Oxide Layer: First, use the small file to gently remove the oxidized layer from the surface of the pins. Be careful not to apply too much force to avoid damaging the pins.

3. Further Cleaning: Next, use fine sandpaper to lightly sand the surface of the pins, further removing any remaining oxides. Again, be gentle to prevent damage.

4. Chemical Cleaning: Use an alcohol swab soaked with a non-acidic cleaner to gently wipe the surface of the pins. This will thoroughly clean the pins and remove any remaining dirt.

5. Apply Conductive Adhesive: Apply conductive adhesive to the surface of the pins, ensuring each pin is evenly coated. Conductive adhesive improves the conductivity of the pins and prevents re-oxidation.

6. Use Anti-Oxidation Liquid: Finally, apply the anti-oxidation liquid to the surface of the pins. The anti-oxidation liquid forms a protective film that prevents the formation of new oxides.

In addition to the above repair steps, consider the following methods to address the oxidation of chip pins:

1. Mechanical Cleaning: Use mechanical force for cleaning, commonly by using sandpaper or abrasive cloth to wipe the surface of the chip pins, removing the oxide layer. This method is suitable for shallow oxidation.

2. Chemical Cleaning: Use chemical reagents to clean the surface of the chip pins and remove the oxide layer. Common reagents include alcohol, acetic acid, and ammonium chloride. Pay attention to the concentration and cleaning time of the reagents to avoid damaging the chip.

3. Ultrasonic Cleaning: Use ultrasonic waves to create tiny bubbles in the cleaning liquid, producing a blasting effect that cleans the surface of the chip pins. This method can remove deeper oxide layers and has a good cleaning effect. However, ensure the proper ratio and temperature of the cleaning liquid to avoid damaging the chip.

To prevent oxidation of chip pins, take preventive measures such as regular equipment maintenance and cleaning the surface of the chip pins to prevent oxide layer formation and ensure normal operation. Additionally, consider using materials with good passivation abilities when selecting electronic components to reduce the risk of pin oxidation.

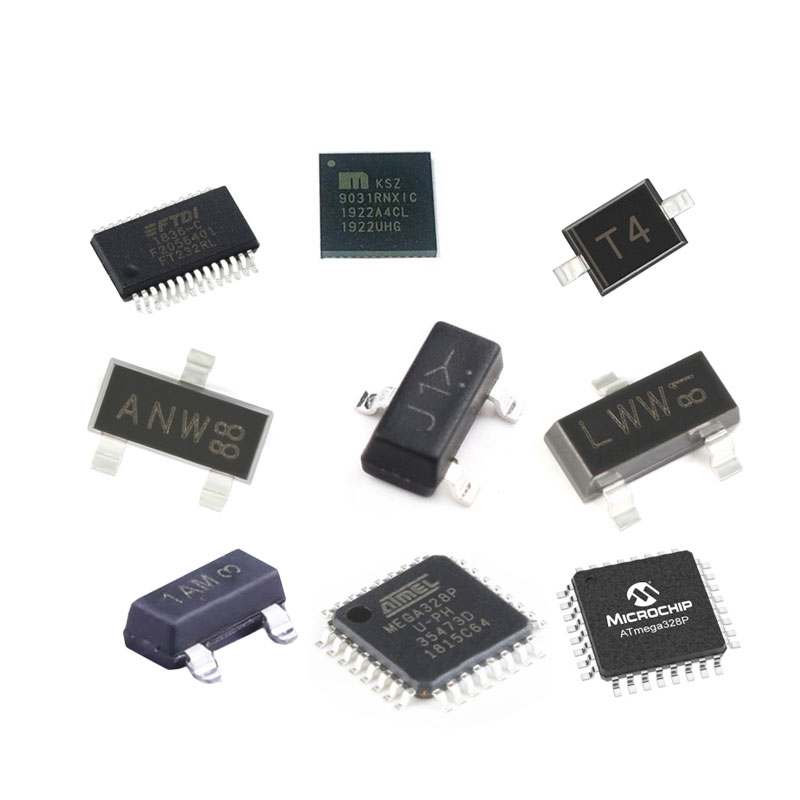

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: global08@eurotech-ic.com

https://www.eurotech-ic.com/