Organic vs. Inorganic Capacitors: Which is Best for Power Filtering?

There are significant differences between organic and inorganic dielectric capacitors in several aspects.

Firstly, in terms of material composition, organic dielectric capacitors are primarily composed of organic materials such as polypropylene and polyethylene. These organic materials impart excellent insulation properties, electron polarity stability, and a wide temperature range suitability to the capacitors. On the other hand, inorganic dielectric capacitors typically use inorganic materials like zinc oxide as the main component, endowing the capacitors with properties such as high temperature resistance, high frequency resistance, and corrosion resistance.

Secondly, regarding application characteristics, organic dielectric capacitors, due to their low dielectric loss and high dielectric constant, are particularly suitable for high-voltage and high-current situations. Meanwhile, inorganic dielectric capacitors exhibit good performance in certain special conditions due to their advantages such as long lifespan and low dissipation factor, especially in environments like high-frequency power capacitors and enclosed capacitors.

When it comes to specific types of capacitors, such as paper capacitors, they utilize thin specialized paper as the dielectric, offering advantages like high capacitance and a wide operating voltage range. However, they have disadvantages such as large volume, low accuracy, high losses, and poor stability. In contrast, mica capacitors, which employ mica as the dielectric, boast high voltage resistance, high accuracy, low losses, and good stability, primarily used in high-frequency oscillation and pulse circuits.

So, which is more suitable for power filtering: organic or inorganic dielectric capacitors?

The main function of a power filter is to obtain a specific frequency power signal or eliminate unwanted frequency signals in the power line, thereby suppressing electromagnetic noise. Choosing between organic and inorganic dielectric capacitors for power filtering mainly depends on their performance characteristics and the specific requirements of the power filter.

Organic dielectric capacitors typically have low dielectric loss and good dielectric constant, making them suitable for high-voltage and high-current situations. Additionally, organic dielectric capacitors are relatively lower in cost, but they may have smaller capacitance and poorer dielectric stability, making them more suitable for operation at low temperature, low voltage, and low frequency.

On the other hand, inorganic dielectric capacitors offer higher capacitance, good thermal stability, and operational stability, enabling them to work under high temperature, high voltage, and high frequency conditions. This advantage makes inorganic dielectric capacitors potentially more advantageous in certain applications with high current and high voltage.

Therefore, for power filtering applications, if the operating environment involves high temperature, high voltage, or high frequency, or there is a demand for large capacitance, inorganic dielectric capacitors may be more suitable. However, if cost is a significant consideration, or the operating environment is mainly at low temperature, low voltage, or low frequency, then organic dielectric capacitors may be a more economical choice.

In conclusion, the choice between organic and inorganic dielectric capacitors for power filtering needs to be balanced based on specific application scenarios and requirements. Before making a decision, it is recommended to conduct detailed performance analysis and testing to ensure that the selected capacitors can meet the requirements of the power filter.

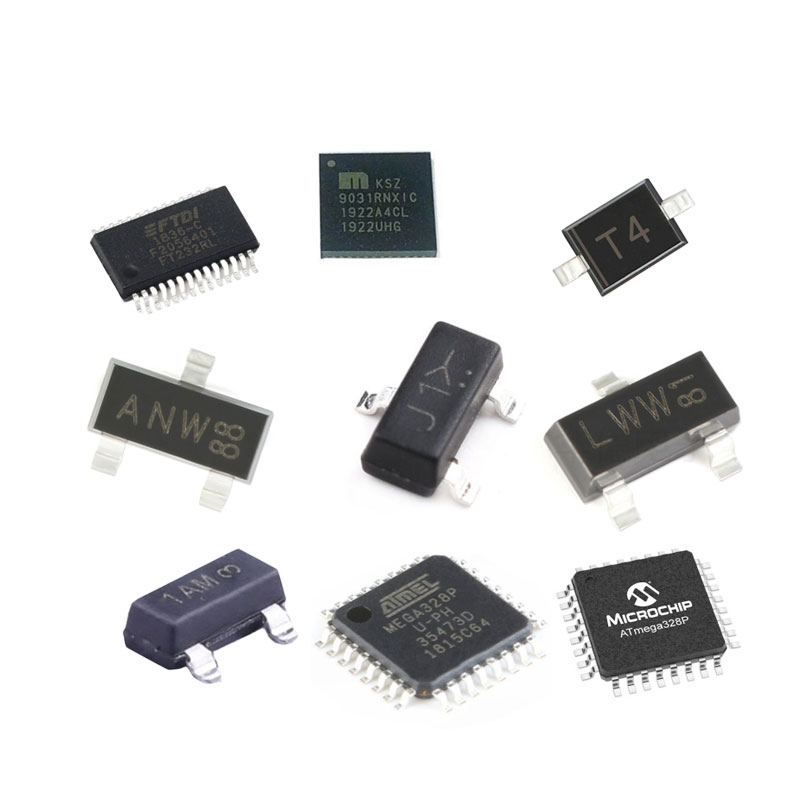

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: global08@eurotech-ic.com

https://www.eurotech-ic.com/