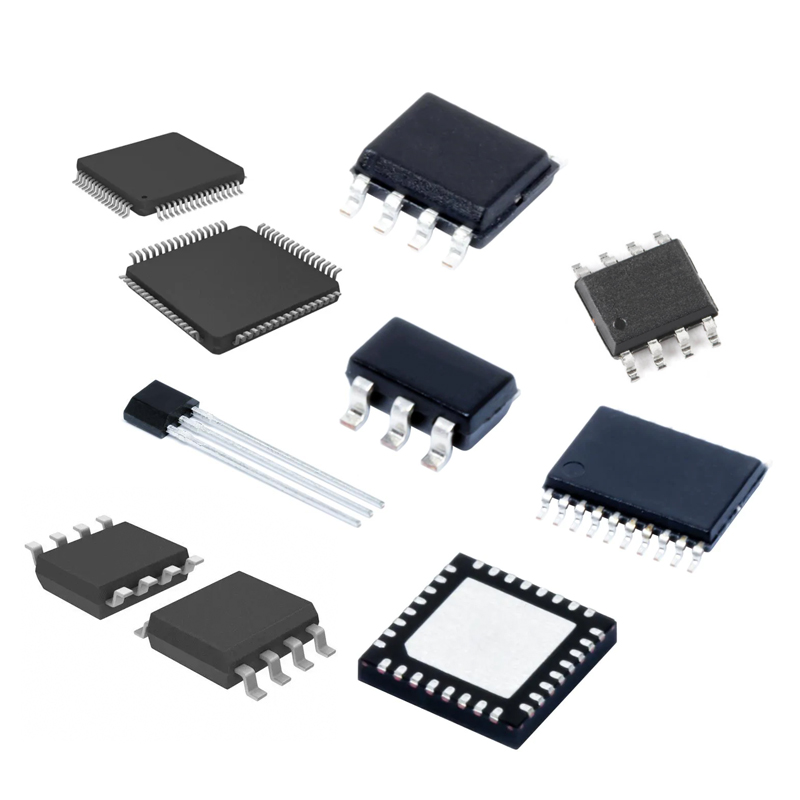

IC chip is the core component of modern electronic products in electronic equipment. IC chip has a very complex mechanism and structure. Therefore, in actual use, how to detect whether the IC chip is normal has become a very important issue. This article will introduce how to detect whether the IC chip is normal.

First, we need to understand under what circumstances there may be problems with IC chips. Generally speaking, IC chips have the following types of problems:

Functional failure: After the chip is powered normally, the chip cannot work normally due to internal circuit components, logic circuits, etc.

Noise power consumption problem: refers to various noise or power consumption problems in the chip itself, causing the chip to not work properly.

External interference: refers to the impact of external noise and interference signals on the chip due to the use environment or signal transmission, disrupting the chip logic and causing the chip to work abnormally.

There are many ways to detect whether the IC chip is normal. Here are a few common methods:

Visual inspection

First, you can check whether the chip is normal through visual inspection. Appearance inspection includes checking whether the chip is damaged, cracked, discolored, etc. If there are any problems with the chip surface, they should be replaced in time.

Electrical test

Electrical testing is one of the important methods to detect whether the chip is normal. You can use electrical testing equipment, such as a multimeter, to test the chip. During the test, you should check whether the pin voltage, current, resistance and other parameters of the chip meet the standards. If any parameter deviates from the standard value, the chip may be abnormal.

Function test

Functional testing is a method to further confirm whether the chip is normal. The chip can be inserted into the circuit and tested for proper functionality. For example, you can test whether the input and output signals, clock signals, reset signals, etc. of the chip are normal.

Spectral analysis

Spectral analysis is a method that can detect defects and chemical composition within a chip. Spectral analysis instruments, such as infrared spectrometer, ultraviolet spectrometer, etc., can be used to perform spectral analysis on the chip. By analyzing the spectrum of the chip, it can be determined whether the chip contains harmful chemicals, such as lead, mercury, etc., and whether it meets environmental standards.

Microscopy

Microscopy is a method that can examine the tiny structures of a chip. You can use a microscope to observe the chip and check whether it is damaged, defective, short-circuited, etc. Microscopic examination can help detect tiny faults in the chip, thereby improving the reliability and stability of the chip.

In addition, professional software can also be used to test IC chips. These software are usually connected to test instruments through computers to detect whether the various logic units in the IC chip are functioning normally, thereby further determining the normality of the IC chip.

By adopting the above methods, the normal operation of the chip can be ensured and faults and losses can be reduced. At the same time, it should be noted that when testing chips, personal safety must be ensured and protective equipment such as gloves and masks must be worn to avoid inhaling harmful substances or being harmed by radiation. The above is an introduction to the detection IC chip.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: info@eurotech-ic.com