Electronic products may face various environments and stresses during use, such as high temperature, low temperature, humidity, vibration, electromagnetic interference, etc. These factors may have a negative impact on the performance and reliability of the product, leading to product failure.

The failure of electronic products can usually be divided into the following stages:

1. Initial failure stage: Initial failure is usually caused by defects in the manufacturing process or material quality issues. For example, problems such as poor solder joint contact, excessive grain size, and insufficient material purity may lead to initial failure. Initial failure usually occurs in the early stages of product use and has a greater impact on product reliability and performance.

2. Failure stage during normal service life: Failure during normal service life is usually caused by factors such as environment and stress. For example, temperature changes, humidity changes, vibration, electromagnetic interference, etc. may cause failure during normal use. Failure during normal service life usually occurs gradually as the product's usage time increases, which has a greater impact on the reliability and performance of the product.

3. Accelerated failure stage: Accelerated failure is usually caused by the influence of environment, stress and other factors on the product, which accelerates the aging or damage of the product. For example, using products under conditions such as high temperature, high humidity, and high voltage may cause accelerated failure. Accelerated failure usually occurs within a short period of time and has a greater impact on product reliability and performance.

4. Sudden failure stage: Sudden failure is usually caused by stress exceeding the product's endurance range or other unpredictable factors. For example, if the product suffers impact, vibration, electric shock, etc. during use, it may cause sudden failure. Sudden failures often have a serious impact on product reliability and performance, and can even lead to product damage or danger.

In order to reduce the failure of electronic products, comprehensive considerations and measures need to be taken in product design, manufacturing, testing and maintenance. For example, the reliability and stability of the product should be considered during the product design stage, high-quality materials and components should be selected, and rigorous testing and verification should be carried out; during the manufacturing process, the stability and controllability of the production process should be ensured to ensure Product quality and performance; comprehensive testing and maintenance should be carried out during the testing and maintenance stages to discover and solve product problems in a timely manner. Through these measures, the reliability and stability of electronic products can be improved and the risk of product failure can be reduced.

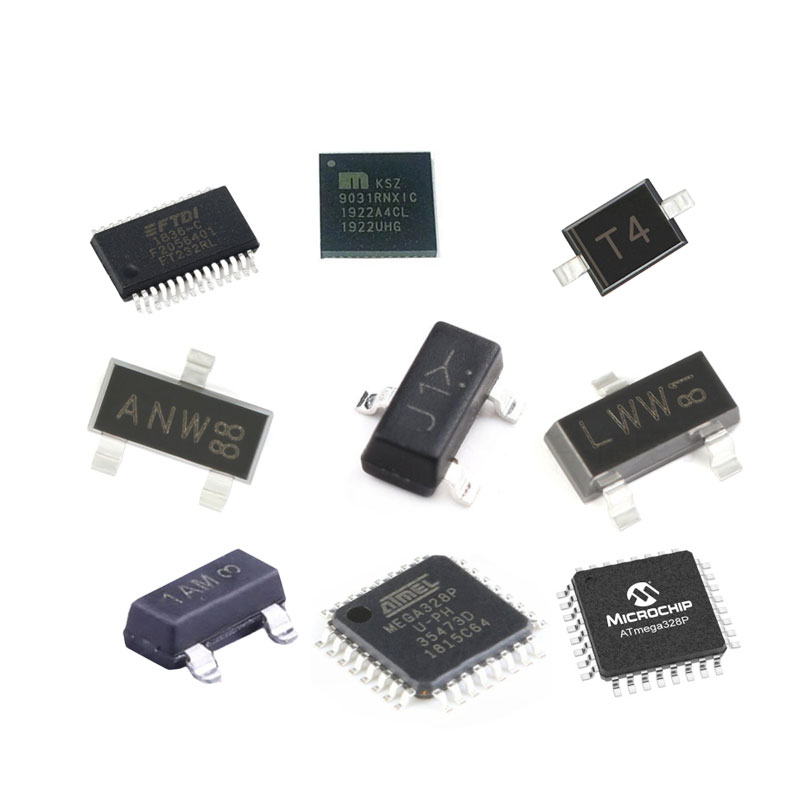

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: info@eurotech-ic.com