Quality inspection of electronic components is a key step to ensure product performance and reliability. Here are some suggestions on how to conduct quality inspections when purchasing electronic components:

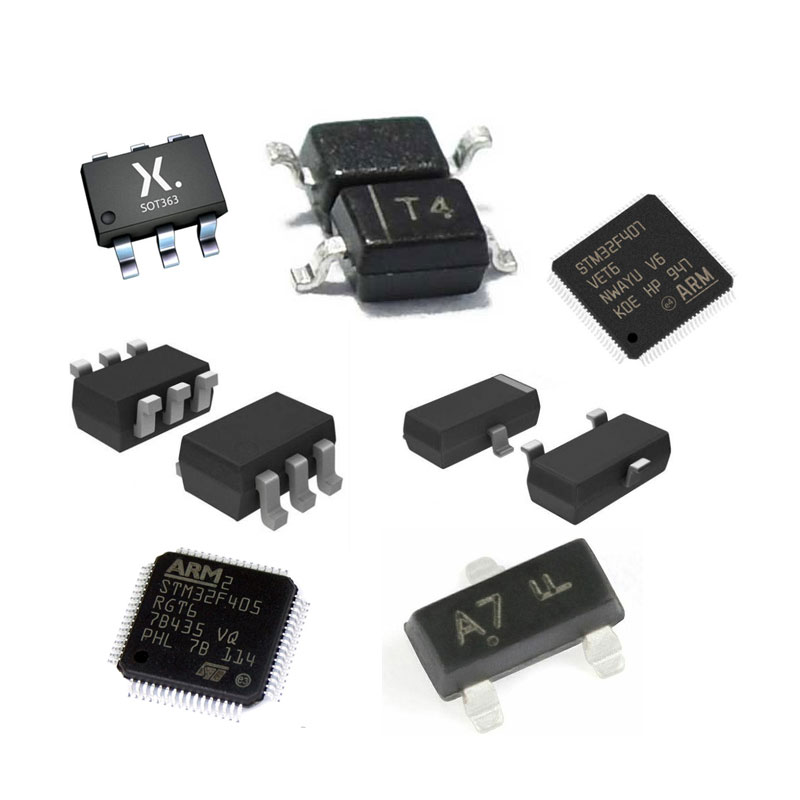

Appearance inspection: First conduct an appearance inspection to ensure that the components have no obvious damage, deformation or welding problems. Pay attention to check the pins, pads, shell and other parts to ensure that there are no obvious defects.

Labeling and packaging: Verify that the markings on components are clear, accurate, and meet specifications. Check that the packaging is intact to prevent damage during transportation.

Specifications and performance testing: Perform performance testing based on the component specifications and technical parameters. This may involve the use of test equipment such as multimeters, oscilloscopes, etc. to verify that the electrical performance of the component meets requirements.

Functional test: Carry out functional test to verify whether the components work normally according to the functions specified by the manufacturer. This can be done by simulating actual application scenarios or using specialized test equipment.

Environmental testing: Where appropriate, environmental testing is performed to simulate the performance of components in different working environments. This may include testing for temperature, humidity, vibration, etc. to ensure that components will function properly under a variety of conditions.

Component parameter measurement: Measure the parameters of components, such as resistance, capacitance, inductance, etc. Make sure these parameters meet the manufacturer's specifications and are within reasonable limits.

Reliability testing: Reliability testing is performed to simulate the performance of components in long-term use. This may include life testing, high temperature and humidity testing, etc. to ensure that components maintain stable performance under various conditions.

X-ray inspection and infrared thermal imaging: For some key components, such as BGA packaged chips, you can consider using X-ray inspection to verify the solder joint connection. Infrared thermal imaging technology can be used to detect the heat distribution of components and find potential problems.

Standardized test methods: Use standardized test methods, such as standards issued by the International Electrotechnical Commission (IEC) or other relevant organizations, to ensure consistency and comparability of tests.

Use a third-party testing agency: When necessary, consider using an independent third-party testing agency to obtain a more objective and neutral quality assessment.

When conducting inspections, be sure to keep detailed inspection records so that you can effectively communicate with electronic component suppliers when problems are discovered and provide reference for subsequent quality management.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: info@eurotech-ic.com