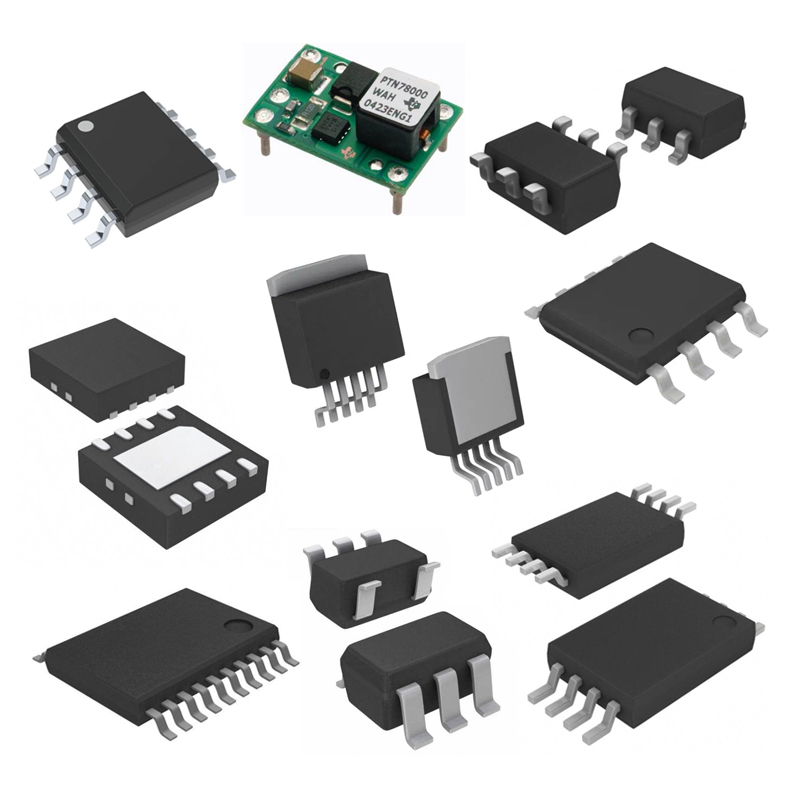

Integrated circuit (IC) chips are the core components of modern electronic products, and the detection of IC chips has become increasingly important. During the production and use of IC chips, damage is easy to occur, and these damages greatly affect the performance and service life of IC chips. Therefore, scientifically and effectively detecting damage to IC chips is crucial to ensuring the quality and reliability of IC chips. The following introduces several common IC chip damage detection methods.

Electrical Characteristics Test

Electrical characteristic testing is one of the most common means of IC chip damage detection. By measuring the electrical characteristic parameters of the IC chip, such as current, voltage, resistance, etc., damage in the IC chip can be identified. Some common electrical characteristic tests include leakage current test, thermal decomposition test, breakdown test, etc. These tests can be measured automatically through instruments and are highly efficient.

Visual inspection

Appearance inspection is to observe the surface of the chip through visual inspection or microscope to check whether the chip has obvious damage or defects. Appearance inspection usually includes the chip's packaging, pins, surface coating, etc.

Mechanical testing

Mechanical testing is to check whether the chip has serious damage or defects by testing the mechanical properties of the chip, such as hardness, toughness, fatigue strength, etc. Mechanical testing usually includes impact testing, bending testing, tensile testing, etc. of the chip.

Infrared thermal image

Infrared thermal imaging mainly uses an infrared camera to capture the thermal imaging of the IC chip surface. Since the loss of electron energy in the IC chip causes a local temperature increase, obvious hot spots can be seen on the thermal image. By analyzing the location and distribution of hot spots, damage to IC chips during production or operation can be identified. The advantage of infrared thermography inspection is that it can be inspected without the IC chip being damaged or disassembled. However, due to the high cost of infrared thermography detection technology, it is rarely used in practice.

Thermal test

Thermal testing is to test the thermal performance of the chip, such as thermal conductivity, thermal expansion, thermal stability, etc., to check whether the chip has serious damage or defects. Thermal testing usually includes high-temperature testing, low-temperature testing, thermal shock testing, etc. of the chip.

Failure analysis

Failure analysis is to analyze the cause of chip failure to determine whether the chip has been damaged or needs further testing. Failure analysis usually includes chemical analysis, physical analysis, electrical analysis, etc. of the chip.

Mechanical testing

Mechanical testing mainly tests IC chips through mechanical loading. Common mechanical loads include tension, compression, bending, etc. By analyzing the deformation and stress distribution of the IC chip under different loads, it can be determined whether the IC chip has problems such as damage, cracks, and displacement. The advantage of mechanical testing is that it can intuitively detect damage and failure of IC chips, but the disadvantage is that it requires specialized equipment and technical support, and the cost is high.

X-ray detection

X-ray detection mainly detects IC chips through the X-ray transmission process. By analyzing the absorption, scattering, diffraction and other phenomena of the IC chip through X-rays, some damage in the IC chip can be identified. The advantage of X-ray inspection is that it can detect IC chips packaged inside the casing and metal damage that is difficult to detect. However, X-ray detection involves radiation problems and requires the use of higher-cost instruments, so it is rarely used in practice.

The continuous updating and development of IC chip damage detection technology ensures the normal operation of the chip. By comprehensively using various detection methods, the quality and reliability of IC chips can be improved, providing a strong guarantee for the majority of IC chip applications.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 83952292

E-mail: info@eurotech-ic.com