Thin film resistors and chip resistors are both commonly used types of resistors in electronic components, and they are widely used in circuits. Although both are resistors, their structures, manufacturing processes, and performance characteristics are different. This article will introduce in detail the difference between thin film resistors and chip resistors.

Thin film resistor

Thin film resistors are resistors made in the form of thin films whose structure consists of a ceramic or glass substrate, a metal film and terminals. Usually, metal films are made of chromium, nickel, copper and other metal materials, and their thickness is about 0.1 microns to 5 microns. Terminals are usually made of metal or alloy materials, such as silver, titanium, copper-nickel alloy, etc.

The manufacturing process of thin film resistors is mainly divided into two methods: physical vapor deposition and chemical vapor deposition. The physical vapor deposition method mainly deposits a metal film on a substrate through vacuum evaporation, sputtering or arcing to form a resistor with a certain resistance value. The chemical vapor deposition method is to deposit a metal film on a substrate through a chemical reaction. Its advantage is that it can produce high-precision and high-stability resistors.

The main characteristics of thin film resistors are as follows:

1. Good stability: The stability of the membrane resistor is very good, its temperature coefficient is usually less than 100 ppm/C, and there will be no obvious resistance value drift due to temperature changes within the operating temperature range.

2. Small size: Due to the advanced manufacturing process of thin film resistors, their size is relatively small and suitable for high-density integrated circuit applications.

3. Fast frequency response: The response speed of thin film resistors is very fast and can be used in high-frequency circuits.

4. High temperature resistance: Thin film resistors have relatively good high temperature resistance and can usually withstand temperatures above 200C.

Chip Resistor

A chip resistor is a resistor made of a ceramic substrate as the basic material. Its structure consists of a ceramic substrate, metal electrodes and solder terminals. The substrate of a chip resistor is usually made of materials such as aluminum oxide or silver phosphate, with a thickness of approximately 0.1mm to 1.2mm. Metal electrodes are usually made of copper, silver nickel and other materials.

The manufacturing process of chip resistors mainly involves depositing metal electrodes on a ceramic substrate to form a resistor body with a certain resistance value, and then welding solder terminals to the metal electrodes to facilitate connection to the circuit.

The main characteristics of chip resistors are as follows.

1. Good stability: The stability of chip resistors is relatively good, and its temperature coefficient is usually less than 200 ppm/C. There will be no obvious resistance value drift due to temperature changes within the operating temperature range.

2. Large size: Since the manufacturing process of chip resistors is relatively simple, its size is relatively large and is not suitable for high-density integrated circuit applications.

3. Slow frequency response: The response speed of chip resistors is relatively slow and is not suitable for use in high-frequency circuits.

4. High temperature resistance: The high temperature resistance of chip resistors is generally poor and can usually only withstand high temperatures below 150°C.

The manufacturing process of chip resistors mainly involves depositing metal electrodes on a ceramic substrate to form a resistor body with a certain resistance value, and then welding solder terminals to the metal electrodes to facilitate connection to the circuit.

The main characteristics of chip resistors are as follows.

1. Good stability: The stability of chip resistors is relatively good, and its temperature coefficient is usually less than 200 ppm/C. There will be no obvious resistance value drift due to temperature changes within the operating temperature range.

2. Large size: Since the manufacturing process of chip resistors is relatively simple, its size is relatively large and is not suitable for high-density integrated circuit applications.

3. Slow frequency response: The response speed of chip resistors is relatively slow and is not suitable for use in high-frequency circuits.

4. High temperature resistance: The high temperature resistance of chip resistors is generally poor and can usually only withstand high temperatures below 150°C.

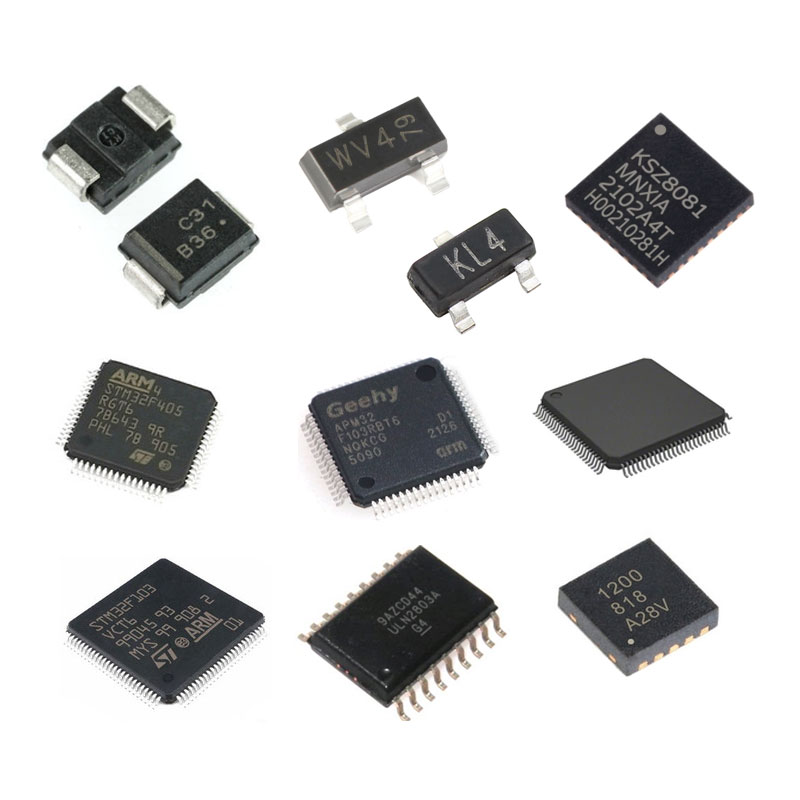

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 8395 9469

E-mail: info@eurotech-ic.com