Packaging of electronic components refers to the process of physically protecting and connecting chips and other electronic components. It plays multiple functions such as insulation, mechanical support, heat dissipation, and electrical connection. Encapsulation not only protects electronic components from the external environment, but also facilitates the assembly and use of circuit boards. Packaging technology has a great impact on the performance, reliability and size of electronic devices.

1. The importance of packaging technology

Packaging technology plays an important role in the modern electronics industry. Its main purpose is to improve product reliability, reduce size, facilitate manufacturing and maintenance, etc. Appropriate packaging design can reduce the difficulty of the assembly process and improve product integration and reliability.

2.Package classification

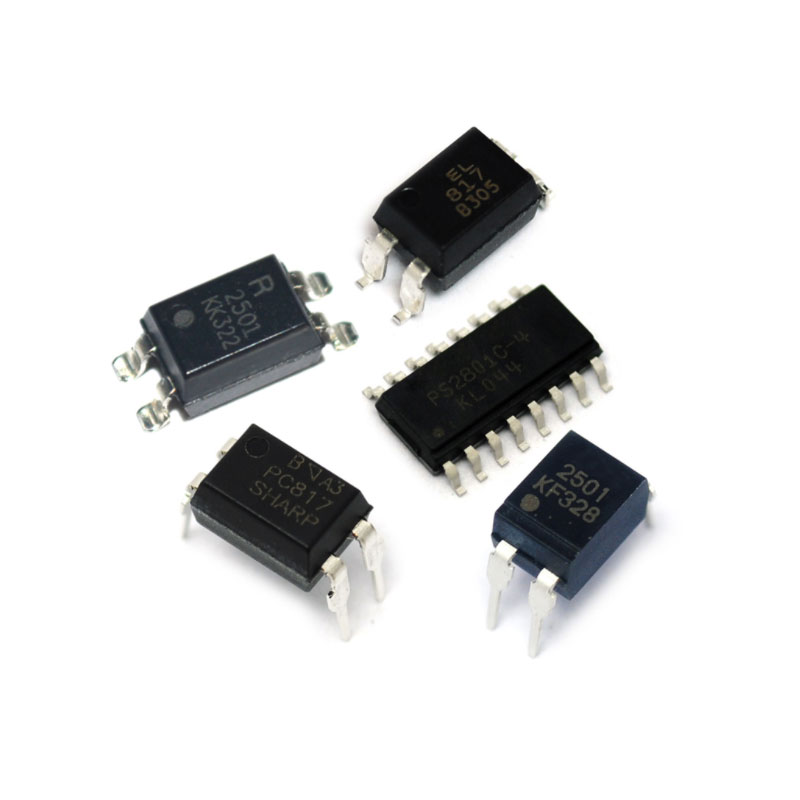

According to different packaging technologies, the packaging of electronic components can be divided into the following types:

-Chip-level packaging: packaging of a single chip. Mainly including bare die packaging, wireless packaging, ball grid array packaging (BGA), solder pin packaging, chip-scale packaging, etc.

-Module-level packaging: that is, packaging multiple chips to form an independent functional module. Mainly include System-in-package, SIP, multi-chip level packaging, multi-layer printed circuit boards, etc.

-Component-level packaging: that is, packaging a series of components, such as diodes, transistors, electrolytic capacitors, etc. It mainly includes surface mount technology (SMT), plug-in packaging, wire connection packaging, etc.

-Packaging materials: Commonly used materials for packaging include plastics, ceramics, metals, etc. These materials have good insulation and conductive properties and can meet the requirements of various electronic packaging.

3. Packaging process

Usually, the electronic component packaging process includes the following steps:

-Bonding: Soldering a chip or electronic component to leads or connection points on a substrate to make an electrical connection.

-Encapsulation: Through injection molding, sealing and other processes, a protective layer is formed between the chip and the leads to play the role of physical protection, insulation and fixation.

-Heat dissipation: Some high-power components require heat dissipation treatment to ensure that the operating temperature of the components is within an acceptable range.

-Marking: In order to facilitate traceability and identification of components, they are often marked during the packaging process, such as printing serial numbers, trademarks, etc.

-Testing and quality control: Test and quality control the packaged components to ensure that their performance meets the requirements.

-Defect handling: During the packaging process, some defective products may be produced, which need to be classified, repaired or eliminated.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 8395 9469

E-mail: info@eurotech-ic.com