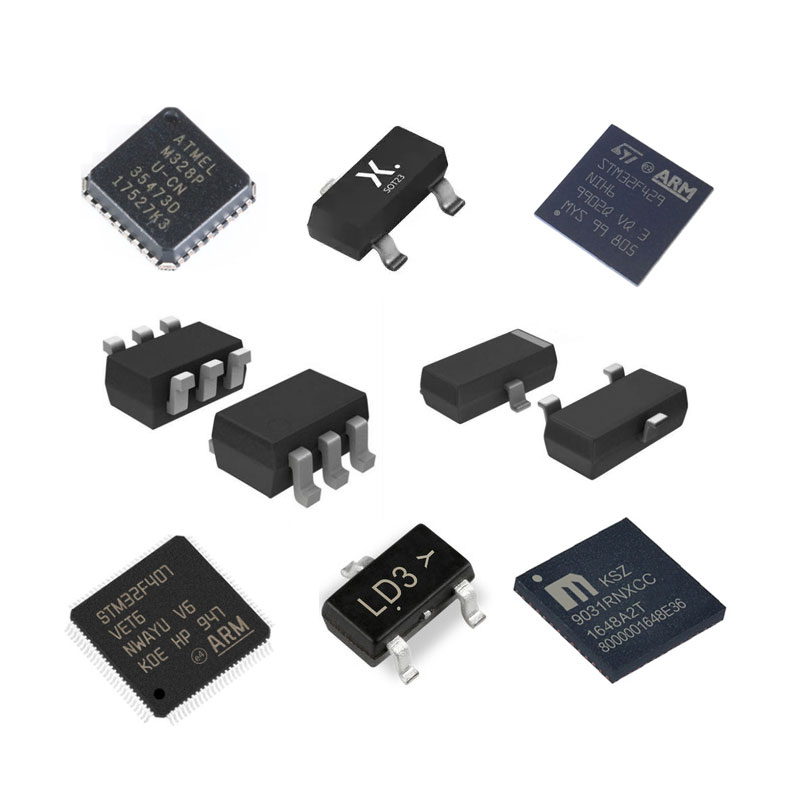

DSO (Dual Small Outline) package is a package type of integrated circuit chip. It is a low-cost, miniaturized package that is widely used in various electronic devices and systems.

DSO packaging is usually used to package medium-sized integrated circuit chips, such as microcontrollers, logic chips, memory chips, etc. It adopts a dual-column pinout design, and the pin count is usually between 8 and 64, which makes the DSO package very suitable for high-density and compact circuit board designs. Features of the DSO package include:

1. Small size: It takes up less space and is suitable for limited PCB (Printed Circuit Board, printed circuit board) space.

2. High pin density: Due to the dual-column pin arrangement, the DSO package can provide higher pin density, which helps to achieve more functions and connections.

3. Good heat dissipation performance: usually adopts a design with a heat dissipation pin (thermal pad), which is helpful for heat dissipation and temperature management.

4. Low cost: Compared with other advanced packaging forms (such as BGA, QFN, etc.), DSO packaging has a lower manufacturing cost, which is conducive to reducing the overall product cost.

It should be noted that the DSO package is different from the SO (Small Outline) package, which only has a single row of pins. The DSO package offers a higher pin density than the SO package at the same size.

DSO package specification

DSO packaging is a common IC packaging type, suitable for medium-sized chips. The following are common DSO package specifications in general:

1. Number of pins: There are many options for the number of pins, usually ranging from 8 pins to 64 pins. Common pin counts include 8, 14, 16, 20, 28, 32.

48 and 64 etc.

2. Pin pitch: The pin pitch is usually 0.65 mm, which is a common pitch size. But DSO seals with other pitch sizes are also possible

installed, such as 0.8mm or 1.27mm.

3. Package shape: Usually a rectangular shape, and its size depends on the number of pins. Common package shapes include SOIC (Small Outline Integrated Circuit) and TSSOP (Thin Shrink Small Outline Package).

4. Encapsulation material: Plastic encapsulation materials such as plexiglass or epoxy resin are usually used.

It should be noted that the specific DSO packaging specifications may vary due to different packaging standards, manufacturers and chip types. Therefore, in practical applications, you should refer to the specification sheet of a specific package and the technical information provided by the manufacturer to obtain accurate package specification information.

Advantages and disadvantages of DSO packaging

As a common IC packaging type, DSO packaging has the following advantages and disadvantages.

The main advantage:

1. Small size: Suitable for limited PCB space, it has advantages in realizing compact and miniaturized circuit design.

2. High pin density: Due to the dual row pin arrangement, the DSO package can provide high pin density. This enables it to provide more functions and connections in the same package size, suitable for chip designs that require more pins.

3. Low cost: Compared with other advanced packaging forms (such as BGA, QFN, etc.), DSO packaging has lower manufacturing costs. This helps reduce overall product cost, and

making it suitable for mass production and consumer electronics markets.

4. Easy to solder and repair: The layout and spacing of the pins are relatively large, making it easy to solder and repair. This makes it more convenient and reliable during manufacture and repair.

Main disadvantages:

1. The number of pins is limited: the number of pins is usually small, generally between 8 and 64. This makes it potentially unsuitable for complex chip designs that require a large number of pins.

beg.

2. Poor heat dissipation performance: The heat dissipation performance is relatively poor. In high-power applications, additional heat dissipation measures may be required to manage the temperature of the chip.

3. Limited electrical performance: Wiring and pin design may have some limitations on electrical performance. Longer pin lengths and routing paths may cause some signal loss and

Delay.

4. Not suitable for high-frequency applications: DSO packages may have some limitations in high-frequency applications due to the characteristics of the package. High-frequency circuit design usually requires more complex package shapes

mode for better signal integrity and immunity to interference.

The advantages and disadvantages of DSO packaging need to be considered comprehensively according to specific application requirements. For some medium-scale chip designs, especially in applications where cost and size are constrained, the DSO package can be a suitable choice.

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 8395 9469

E-mail: info@eurotech-ic.com