As an important power management device in electronic equipment, the power IC chip undertakes various functions such as conversion, voltage regulation, and protection. However, in practical applications, the heating problem of the power IC chip is often concerned. This article will introduce in detail the reasons for the heating of the power IC chip.

Causes of power supply IC heating

1. The working temperature is too high

The power IC chip will generate heat when it is working, and when the temperature of the working environment is too high, it will become difficult to dissipate the heat of the power IC chip, which will cause the temperature of the chip to continue to rise. Once the maximum temperature that the chip can withstand is exceeded, it will cause damage or failure of the chip.

2. Poor heat dissipation

The heat of the power IC chip needs to be dissipated through heat dissipation, usually in three ways: conduction, convection and radiation. However, if the heat dissipation of the chip is not good, the heat will not be dissipated in time, so that the temperature of the chip will continue to rise.

3. Overvoltage and overcurrent

When the power IC chip is working, if the voltage or current at the input terminal exceeds the maximum tolerance range of the chip, it will cause the chip to overvoltage or overcurrent. At this time, the protection circuit inside the chip will start to protect the chip from damage, but it will also cause the chip to heat up.

4. Unreasonable design

In the design of the power IC chip, if the consideration is not thorough or the design is unreasonable, it will also cause the chip to overheat. For example, the current design of the internal circuit of the chip is too large, the resistance is too small, etc., which may lead to increased loss of the chip, resulting in excessive heat generation.

5. Large line resistance and current

The power IC chip needs to withstand a certain current and voltage when it is working. When the current is too large or the line resistance is too large, the loss of the power IC chip will increase, resulting in heat generation. Especially in the case of low voltage and high current, the heat loss of the power IC chip will be more obvious.

The solution to the heating of power supply IC

In order to reduce the heat generation of the power IC chip, we can start from the following aspects:

1. Optimize circuit design

By optimizing the circuit design, reducing the line resistance and current, the power consumption and loss of the power IC chip are minimized, thereby reducing the heat generation of the chip. This goal can be achieved by means of low power consumption power IC chips and reasonable circuit layout.

2. Strengthen heat dissipation

The heat dissipation effect of the power IC chip directly affects its temperature, so strengthening heat dissipation can effectively reduce the temperature of the chip. Heat dissipation devices such as heat sinks and fans can be used to enhance the heat dissipation of the chip. At the same time, attention should be paid to the installation and layout of the heat dissipation devices.

3. Control the working temperature

In practical applications, the heat generation of the chip can be reduced by controlling the operating temperature of the power IC chip. The purpose of controlling the working temperature can be achieved by adjusting the output voltage, controlling the input voltage, etc. At the same time, care should be taken not to let the working temperature of the chip exceed its tolerance range.

4. Choose the right chip

When selecting a power IC chip, the appropriate chip should be selected according to the actual application scenario to reduce the heat generation of the chip. You can choose a chip with low power consumption and high efficiency, and pay attention to the parameters such as the tolerance range and specifications of the chip.

5. Improve power efficiency

The efficiency of the power supply IC directly affects its heat generation, so improving the power supply efficiency can also effectively reduce the heat generation of the chip. The efficiency of the power supply can be improved by adopting high-efficiency switching power supply and improving the conversion efficiency of the power supply.

To sum up, by optimizing circuit design, enhancing heat dissipation, controlling operating temperature, selecting appropriate chips, and improving power efficiency, the heating of power IC chips can be effectively reduced, thereby ensuring the stability and reliability of power IC operations.

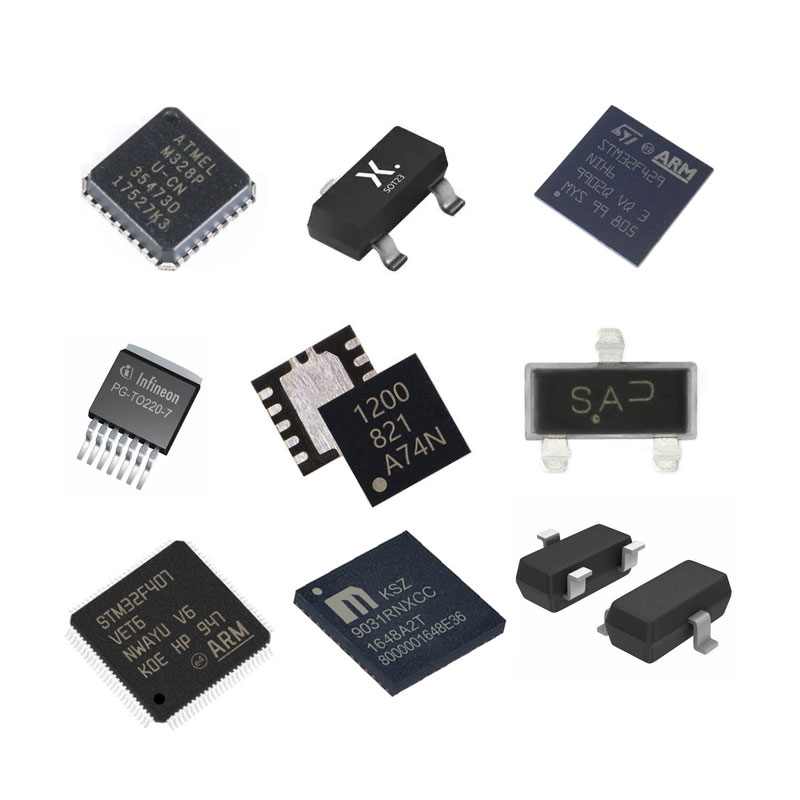

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 8395 9469

E-mail: info@eurotech-ic.com