Chip packaging refers to connecting the circuit pins on the silicon chip to the external wiring with wires, the purpose is to facilitate the connection with other components, and the packaging form refers to the shell used to install the semiconductor integrated circuit chip. Packaging the chip can play a lot of roles, not only to install, fix, seal, and protect the chip, but also to realize the connection between the internal chip and the external circuit. However, when packaging the chip, it must be kept isolated from the outside world, which can effectively prevent impurities in the air from corroding the chip circuit and causing a decline in electrical performance.

After the chip is packaged, it can be more convenient to install and transport, because the quality of the chip technology will directly affect the performance of the chip itself and the design and manufacture of the printed circuit board, so the chip packaging technology is very important. If you want to know whether the chip packaging technology is advanced, you can look at the ratio of the chip area to the packaging area. If the ratio is closer to 1, it means that the chip packaging technology is more advanced.

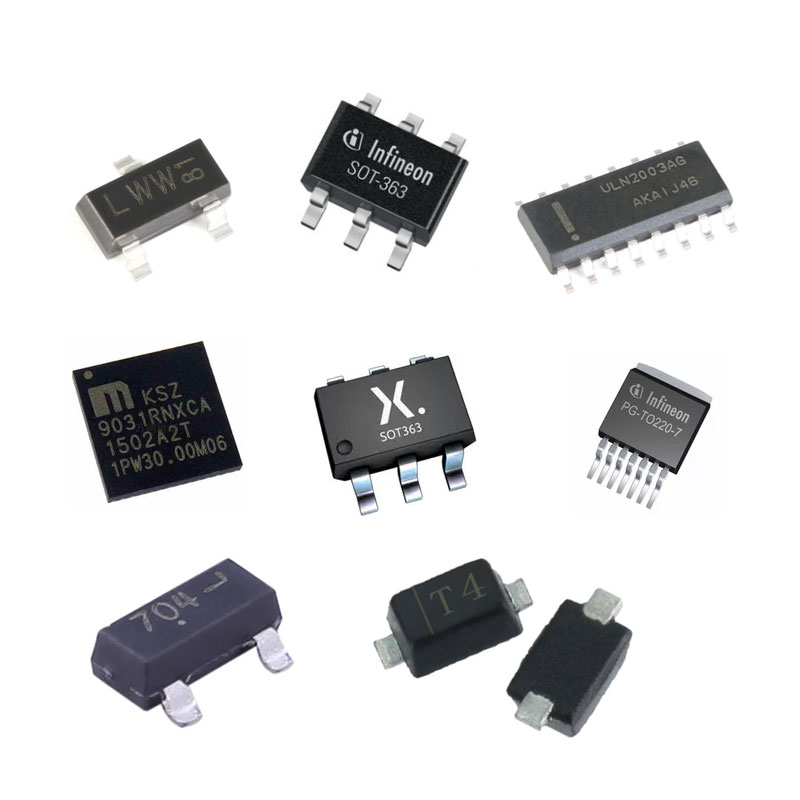

There are also many ways to package chips, which can be classified into pin insertion type, surface mount type, and advanced packaging according to the package's outline size and structure. If it is classified according to the packaging material of the chip, it can be divided into metal packaging, ceramic packaging, plastic packaging and metal-ceramic packaging. In addition, it can also be classified according to the shape of the chip and the substrate type of the chip. With the development of integrated circuit technology, the packaging requirements for chips are more stringent.